The Challenge

A research and development company approached Wrabacon looking to start a new product line. The process would involve a stack of trays being presented to the system, upon which these trays would need to be denested to be individually filled with product. Following this, the filled trays would need to be restacked to the same height. With each filled tray averaging about 45 pounds, and the stacks consisting of 24 trays apiece, it was extremely clear that an automated system was the only solution that would be efficient and ergonomically safe.

The Solution

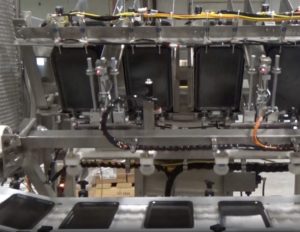

Wrabacon custom designed and manufactured a tray stacker/denesting system that handles trays of product. The trays sit on modified pallets, and the system denests and stacks trays at a rate of 6 per minute.

Here’s how it works: There is one cell for each of the denest and stack stations. Operators manually load full pallets, filled with product, onto a pallet conveyor. The first pallet moves into position and the system starts by raising the entire stack of trays off the pallet, and up to the cross-conveyor height. Cylinders extend — to lift the top tray out of the stack — and a cross cylinder pushes the tray, from the stack onto the cross-conveyor. After the tray has been denested, the lifting mechanism indexes up — one pitch. The second tray is then denested, and pushed onto the cross conveyor. Meanwhile, the first tray moves down the conveyor, and the cured product is taken out. The empty tray then travels downstream, where it is stopped and filled with new product. The empty pallet on the denesting cell is indexed away from the lifting mechanism, and then transported to the stacking cell via a conveyor. A new full pallet enters, ready for denesting.

The stacking end reverses the infeed process. The empty pallet from the denesting side is indexed into position, and the stacker starts. Each tray is pushed into the system from a conveyor, and the machine indexes down to be ready for the next tray. This will continue until 24 trays have been stacked onto the pallet. The full pallet is then indexed out of the stacking position, and a new empty pallet is then indexed into position. The process then repeats, ensuring maximum success and efficiency.

People care immensely about the quality of their bread. Everybody loves the aromatic taste, smell, and feel of fresh-baked artisan bread — but few have the patience to prepare it from scratch. While frequenting the local bakery is one option, it’s not convenient for busy people on the move. A good middleground can be found in “parbaking,” wherein a bread product is partially baked, and then quickly frozen for storage. If done correctly, parbaking provides bread lovers with the look, taste, and feel of fresh bread, but none of the stress.

People care immensely about the quality of their bread. Everybody loves the aromatic taste, smell, and feel of fresh-baked artisan bread — but few have the patience to prepare it from scratch. While frequenting the local bakery is one option, it’s not convenient for busy people on the move. A good middleground can be found in “parbaking,” wherein a bread product is partially baked, and then quickly frozen for storage. If done correctly, parbaking provides bread lovers with the look, taste, and feel of fresh bread, but none of the stress. Who doesn’t enjoy fresh corn? Easy to cook, affordable, and delicious, corn is an American institution: whether it’s being grilled for an Independence Day barbeque or served beside the Thanksgiving turkey, it’s a wholesome part of the nation’s identity.

Who doesn’t enjoy fresh corn? Easy to cook, affordable, and delicious, corn is an American institution: whether it’s being grilled for an Independence Day barbeque or served beside the Thanksgiving turkey, it’s a wholesome part of the nation’s identity. More efficient processes mean more profit. This was exactly the case with a food manufacturer that wanted to increase packaging production for their frozen dough balls. They turned to Wrabacon requesting a system design and install that would receive frozen dough balls from a freezer, singulate them (separate them into individual pieces), and transfer them to two automatic bagging machines. This one change would help them increase their production capabilities dramatically.

More efficient processes mean more profit. This was exactly the case with a food manufacturer that wanted to increase packaging production for their frozen dough balls. They turned to Wrabacon requesting a system design and install that would receive frozen dough balls from a freezer, singulate them (separate them into individual pieces), and transfer them to two automatic bagging machines. This one change would help them increase their production capabilities dramatically. Wrabacon was tasked with designing and manufacturing a series of conveyors that transport filled plastic containers from two existing fillers to two existing spot pack machines. The system needed to be designed so that each filler can feed each spot pack machine utilizing reversing belts. The containers will be produced at the rate of 180 per minute per filling machine. After the spot pack machine, spot packs need to be elevated and fed into a new palletizing line at the rate of 30 packs per minute.

Wrabacon was tasked with designing and manufacturing a series of conveyors that transport filled plastic containers from two existing fillers to two existing spot pack machines. The system needed to be designed so that each filler can feed each spot pack machine utilizing reversing belts. The containers will be produced at the rate of 180 per minute per filling machine. After the spot pack machine, spot packs need to be elevated and fed into a new palletizing line at the rate of 30 packs per minute.