The Challenge

People care immensely about the quality of their bread. Everybody loves the aromatic taste, smell, and feel of fresh-baked artisan bread — but few have the patience to prepare it from scratch. While frequenting the local bakery is one option, it’s not convenient for busy people on the move. A good middleground can be found in “parbaking,” wherein a bread product is partially baked, and then quickly frozen for storage. If done correctly, parbaking provides bread lovers with the look, taste, and feel of fresh bread, but none of the stress.

People care immensely about the quality of their bread. Everybody loves the aromatic taste, smell, and feel of fresh-baked artisan bread — but few have the patience to prepare it from scratch. While frequenting the local bakery is one option, it’s not convenient for busy people on the move. A good middleground can be found in “parbaking,” wherein a bread product is partially baked, and then quickly frozen for storage. If done correctly, parbaking provides bread lovers with the look, taste, and feel of fresh bread, but none of the stress.

Packaging and providing parbaked artisanal bread products to customers, though, is a great deal more complex. Precision is necessary. Proper timing is everything. That’s why a local wholesale bakery, who specializes in parbaked frozen breads and bread rolls, turned to Wrabacon for solutions.

The Wrabacon Solution

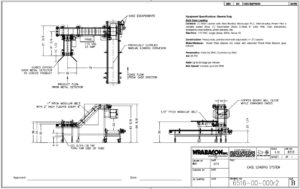

Wrabacon got to work by designing a custom packing system for this bakery’s precise needs. This meant manufacturing a case load system capable of bulk load cases of 16 oz. and 24 oz. of wrapped, frozen dough balls, per case: these dough balls are to be produced at a maximum rate of 60 per minute.

Here’s how it works: the bags transfer, single file, from an existing metal conveyer onto another conveyer that is 36” long. This second conveyer feeds a flighted inline conveyer, which is traveling perpendicular to the main line.

The bags travel up the incline. They pass through a hopper and into an empty awaiting case, which sits on a conveyer positioned underneath the hopper. Note, a sensor is located in the hopper for the purpose of counting the bags as they pass by. Once the proper count has passed through, the hopper closes. At this point, as the filled case is moved out of the way — to make way for a new, empty case — the closed hopper accumulates any incoming bags. This way, once the new empty case has been positioned, the accumulated bags will cleanly drop right into the case.

From here, the bagged dough exits a new Kwik Lok machine. It drops, one at a time, onto a flighted inline conveyer, which then transports the dough balls onto the existing freezer conveyer. The dough balls then drop, single file, onto the freezing conveyer prior to feeding the existing metal detecting conveyer. This conveyer will only be used when the Kwik Lok machine is running.

Wrabacon manufactured and supplied the following equipment for this project:

- Metal detecting discharge conveyer to feed incline

- Inclined conveyer with high friction inserts

- Stainless steel gating hopper

- Set of pneumatic escapements (to be mounted on manual loading conveyer)

- Control system

All components in the system were manufactured in stainless steel to meet washdown and sanitary requirements.