Conveyor Case Studies

Wrabacon Case Studies

Ice Cream Manufacturer

Problem: Eliminate repetitive motion in a hand palletizing operation.

Solution: Wrabacon custom designed and manufactured a stainless steel box stacker and stainless steel conveyor system. The system was designed to receive boxes from an automatic taper (by others). The stacker up stacked two boxes and then transported them to a transfer. The transfer then pushed the stacked boxes 90 degrees onto the stainless steel conveyor, which is located in a storage freezer, for delivery to the palletizing area.

Stainless Steel Conveyor System Video

Wrabacon custom designed and manufactured a stainless steel box stacker and stainless steel conveyor system. The system was designed to receive boxes from an automatic taper (by others). The stacker up stacked two boxes and then transported them to a transfer. The transfer then pushed the stacked boxes 90 degrees onto the stainless steel conveyor, which is located in a storage freezer, for delivery to the palletizing area.Food Manufacturer

Problem: Feed three lines of prepared food trays into a spiral freezer.

Solution: Wrabacon designed and manufactured a multi-lane custom product handling system. This system was designed to accept trayed product from one of three production lines. The trays were then orientated, grouped and transferred onto a main line for insertion into the freezer. This custom system manufactured in stainless steel included three cross over conveyors and a 42-inch wide main line conveyor.

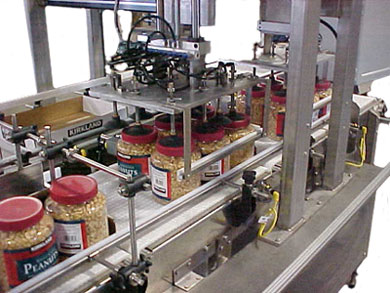

Peanut Processor

Problem: Replace a hand packing line to an automated system.

Solution: Wrabacon designed and manufactured an automated pick and place tray packing line to receive 2 lbs plastic jars at a rate of 120 jars per minute. The system was designed for easy change over so that a pattern of 2 x 3 or 3 x 4 could be picked. The pick and place system collated the jars into the desired to pattern Once the pattern was established a tray was introduced into the system, the tray was stopped and the pick and place system would pick up the pattern and deposit it into the tray. The tray was then released to another operation.