The Challenge:

A food manufacturing company approached Wrabacon looking to create a new product line of sealed cans, which could be loaded and packaged into trays. They were seeking out a system that could stack these trays at a speed that could keep up with demand.

While keeping up with rate was a necessity, precision was just as important — because any damage sustained to the product, from a stack falling over, would almost certainly leave it unsuitable for distribution. The system needed to produce a sturdy stack every time. With this in mind, Wrabacon got started.

The Solution:

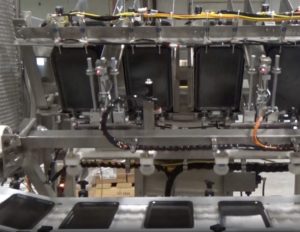

Wrabacon custom-designed a bundle stacking system that is used to stack trays that have an array of sealed cans. The tray rate is 28 per minute. The stacker can stack either two high, or be used as a pass-through device, without any stacking. The pass-through tray is up to 18” wide.

The trays transfer to the stacker with the wide edge leading. It transfers onto twin belts and travels to the stacking station, where it is stopped using a pneumatic cylinder. When in position, the bundle is lifted vertically past a set of pneumatic ledges. The ledges extend, the lift cylinder retracts, and the tray now sits on the two ledges. When the next bundle arrives, it is stopped — and at this point, the upper bundle is released, placing it on top of the awaiting bundle, completing the two high stack. The newly formed stack is then released downstream for further production.

People care immensely about the quality of their bread. Everybody loves the aromatic taste, smell, and feel of fresh-baked artisan bread — but few have the patience to prepare it from scratch. While frequenting the local bakery is one option, it’s not convenient for busy people on the move. A good middleground can be found in “parbaking,” wherein a bread product is partially baked, and then quickly frozen for storage. If done correctly, parbaking provides bread lovers with the look, taste, and feel of fresh bread, but none of the stress.

People care immensely about the quality of their bread. Everybody loves the aromatic taste, smell, and feel of fresh-baked artisan bread — but few have the patience to prepare it from scratch. While frequenting the local bakery is one option, it’s not convenient for busy people on the move. A good middleground can be found in “parbaking,” wherein a bread product is partially baked, and then quickly frozen for storage. If done correctly, parbaking provides bread lovers with the look, taste, and feel of fresh bread, but none of the stress. Who doesn’t enjoy fresh corn? Easy to cook, affordable, and delicious, corn is an American institution: whether it’s being grilled for an Independence Day barbeque or served beside the Thanksgiving turkey, it’s a wholesome part of the nation’s identity.

Who doesn’t enjoy fresh corn? Easy to cook, affordable, and delicious, corn is an American institution: whether it’s being grilled for an Independence Day barbeque or served beside the Thanksgiving turkey, it’s a wholesome part of the nation’s identity.